Auto body fasteners like bolts, nuts, clips, and rivets are crucial for Mercedes Benz repair and car body restoration, ensuring proper alignment and structural integrity. High-quality, corrosion-resistant fasteners with advanced strength and precise manufacturing extend repair life. Expert installation techniques using specialized tools minimize damage risk. This combination provides durable, reliable collision repair services, preserving vehicle structural integrity in challenging environments.

Auto body fasteners, often overlooked, play a pivotal role in ensuring structural integrity and long-term repair outcomes for vehicles. This article delves into the intricate world of these fasteners, exploring their types and functions. We examine how quality and installation techniques significantly impact durability. Additionally, we uncover key factors influencing the longevity of repairs over time, providing insights that are vital for both professionals and car owners alike when dealing with auto body fasteners.

- Understanding Auto Body Fastener Types and Functions

- Impact of Quality and Installation Techniques on Durability

- Longevity: Factors Affecting Repair Outcomes Over Time

Understanding Auto Body Fastener Types and Functions

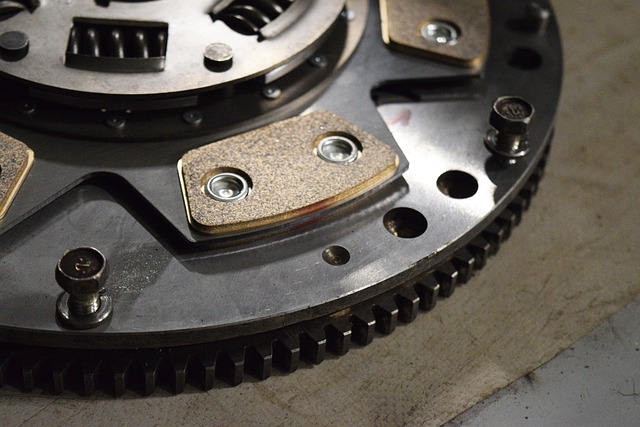

Auto body fasteners play a pivotal role in ensuring the structural integrity and long-lasting quality of vehicle repairs, particularly in meticulous processes like Mercedes Benz repair or car body restoration. These fasteners, ranging from bolts and nuts to clips and rivets, serve as the building blocks for autobody repairs, holding various components together during the reconstruction process. Their primary function is to maintain the alignment and stability of panels, frames, and other parts, thereby dictating the overall success of the repair.

Understanding different auto body fastener types and their functions is crucial for achieving optimal results in any car body restoration project. For instance, high-strength bolts designed for specific vehicle models may be necessary to withstand structural stresses during an intensive Mercedes Benz repair. Proper selection ensures that panels fit seamlessly, preventing future misalignments or weak points that could compromise the integrity of the vehicle. This meticulous attention to detail is what separates a successful car body restoration from ordinary autobody repairs.

Impact of Quality and Installation Techniques on Durability

The quality of auto body fasteners plays a pivotal role in determining the longevity and durability of collision repair services. Using high-quality fasteners ensures that all components are securely fastened, preventing future loose parts that can compromise structural integrity. Premium fasteners often feature enhanced corrosion resistance, superior tensile strength, and precise manufacturing tolerances, contributing to a longer lifespan and maintaining the car’s structural stability over time.

Effective installation techniques are equally critical. Skilled technicians employ specialized tools and adhere to strict protocols to ensure each fastener is correctly torqued and aligned. This meticulous approach minimizes the risk of damage to surrounding surfaces or components, enhancing the overall durability of the repair. Ultimately, combining high-quality fasteners with expert installation results in a robust car bodywork solution that stands the test of time, ensuring customers benefit from reliable collision repair services for years to come.

Longevity: Factors Affecting Repair Outcomes Over Time

The longevity of auto body repairs is significantly influenced by various factors, including the quality and type of fasteners used. Auto body fasteners play a crucial role in ensuring that repairs hold up over time, especially in harsh environmental conditions. High-quality, durable fasteners like specialized bolts, rivets, and clips are designed to withstand corrosion, vibration, and impact, thereby extending the lifespan of repairs. These fasteners also ensure proper alignment and tension, which is vital for maintaining structural integrity.

On the other hand, subpar fasteners might fail over time, leading to costly touch-ups or even more severe damage. Factors such as material composition, manufacturing quality, and installation techniques all contribute to the longevity of auto body repairs. For instance, paintless dent repair techniques often rely on advanced fasteners that allow for precise adjustments, minimizing the need for additional painting or patching. Similarly, when addressing car scratch repair, using appropriate fasteners can help ensure that new coatings adhere properly, preventing further damage and maintaining a sleek finish.

Auto body fasteners play a pivotal role in ensuring long-term repair outcomes for vehicles. Understanding the various types, their functions, and the impact of quality and installation techniques is essential. High-quality fasteners installed correctly significantly enhance durability, while subpar materials or shoddy work can lead to premature repairs. Key factors such as corrosion resistance, material strength, and environmental exposure further influence longevity. By prioritizing these aspects, automotive professionals can deliver more lasting repairs, ultimately saving time and costs in the long run for vehicle owners.