Auto body fasteners adhering to Original Equipment Manufacturer (OEM) standards are vital for both safety and quality in collision repair. These specifications ensure structural integrity, compatibility with specific vehicle models, and durability against future issues like rust or loose parts. By following OEM guidelines, technicians achieve optimal structural integrity and detailing, enhancing the overall driving experience while preserving vehicle value and owner satisfaction. Essential types include bolts, nuts, rivets, and nails, each serving distinct purposes in assembly, maintenance, and repair, aiming to restore vehicles to their pre-accident condition efficiently.

In the automotive industry, auto body fasteners are critical components ensuring vehicle structure integrity and safety. To maintain optimal performance, these fasteners must meet Original Equipment Manufacturer (OEM) specifications. This article delves into the importance of OEM standards for auto body fasteners, highlighting their role in longevity and safety. We explore common types, their applications, and why adhering to OEM guidelines is paramount for both manufacturers and consumers alike.

- Understanding OEM Specifications for Auto Body Fasteners

- The Role of Quality in Ensuring Longevity and Safety

- Common Types of Auto Body Fasteners and Their Applications

Understanding OEM Specifications for Auto Body Fasteners

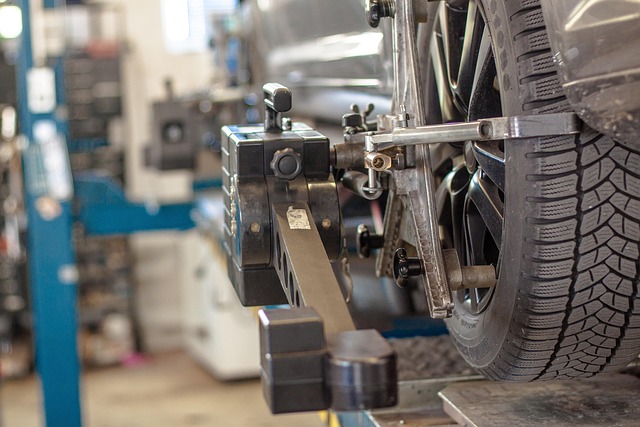

When it comes to auto body fasteners, understanding OEM (Original Equipment Manufacturer) specifications is paramount for ensuring quality and safety in collision repair. These standards set by automakers dictate the exact dimensions, materials, and performance criteria that parts must meet to be considered original equipment. For instance, OEM specs may include details on tensile strength, thread size, and material composition to guarantee both durability and compatibility with specific vehicle models.

Meetings these stringent requirements is vital not just for structural integrity but also for the overall quality of auto detailing. Properly fitted fasteners prevent future issues like loose parts, rust, or further damage during collision repair processes such as car dent repair. By adhering to OEM guidelines, technicians can ensure that repaired vehicles not only look their best but also perform optimally on the road.

The Role of Quality in Ensuring Longevity and Safety

In the realm of auto body repair and restoration, quality is paramount. Auto body fasteners that meet Original Equipment Manufacturer (OEM) specifications play a pivotal role in ensuring both longevity and safety. These components are the unsung heroes that hold a vehicle’s exterior together, from fenders to door panels. Using fasteners that adhere to stringent OEM standards guarantees structural integrity, preventing future damage and ensuring the vehicle retains its original strength and aesthetic appeal.

The significance of quality auto body fasteners extends beyond mere structural stability. In the realm of automotive collision repair and paintless dent repair, these fasteners enable precise repairs, minimizing the need for extensive rework. By maintaining OEM specifications, repair technicians can achieve seamless results, preserving the vehicle’s value and its owner’s satisfaction. This attention to detail not only facilitates efficient auto collision repair but also contributes to a lasting, safe driving experience.

Common Types of Auto Body Fasteners and Their Applications

Auto body fasteners are essential components used in various applications within the automotive industry, playing a crucial role in vehicle assembly and maintenance. These fasteners come in numerous types, each designed for specific tasks, ensuring structural integrity and aesthetic appeal. One of the most common is the bolt, ideal for securing metal panels and components due to its strength and versatility. Nuts, another staple, are used in conjunction with bolts to create a secure fastening system.

In the realm of auto detailing and body restoration, specialized fasteners like rivets and nails find their place. Rivets, known for their permanent bonding, are often employed in delicate repair work to reinforce small areas without compromising aesthetics. Nails, while simpler, are suitable for temporary fixes or when precise alignment isn’t a priority. Collision repair shops rely on these fasteners to patch up damages swiftly, ensuring vehicles return to their pre-accident condition through meticulous use of the right tools and materials.

When selecting auto body fasteners, adhering to OEM specifications is paramount for both performance and safety. By prioritizing quality and understanding the diverse applications of different fastener types, you ensure your vehicle’s structural integrity and longevity. Auto body fasteners, after all, play a crucial role in maintaining the overall stability and safety of a vehicle.