Auto body fasteners like rivets, bolts, screws, and clips are crucial for structural integrity in car repairs, with each type serving unique purposes. Proper preparation, including cleaning, priming, and using advanced tools, ensures optimal adhesion. Correct installation methods, alignment, and regular inspections maintain safety and aesthetics, utilizing high-quality fasteners resistant to corrosion.

Avoid common pitfalls with auto body fasteners and ensure a durable, seamless repair. This guide breaks down the essentials of auto body fastener types, their unique applications, and proper preparation techniques. From surface cleaning to advanced treatment methods, learn how to optimize installation for long-lasting results. Discover expert tips to prevent missteps, ensuring your repairs stand the test of time. Master these strategies for superior auto body fastening practices using the right tools and techniques.

- Understanding Auto Body Fastener Types and Their Uses

- Preparation: Surface Cleaning and Treatment Techniques

- Installation Tips to Ensure Secured and Longevity Fasteners

Understanding Auto Body Fastener Types and Their Uses

Auto body fasteners play a critical role in ensuring the structural integrity and overall quality of car body repair and collision repair center operations. Understanding the diverse range of auto body fasteners and their specific uses is essential for any professional in the automotive industry, as it enables them to make informed decisions during the restoration process. Each type of fastener serves a unique purpose, from securing panels and components to enhancing the overall durability of the vehicle after car damage repair.

Knowing when to employ rivets, bolts, screws, or clips is vital for achieving precise and long-lasting results in any collision repair center. For instance, rivets are commonly used for permanent fastening due to their ability to create a strong, unremovable bond, while bolts and screws offer versatile attachment solutions suitable for various materials. Clips, on the other hand, provide quick and temporary hold, facilitating efficient assembly during car body repair procedures. This knowledge equips technicians with the tools to navigate complex repairs, ensuring not just surface-level restoration but also the structural soundness of the vehicle in question.

Preparation: Surface Cleaning and Treatment Techniques

Before securing any auto body fasteners, a thorough preparation process is essential to ensure optimal adhesion and long-lasting results. The first step begins with surface cleaning, removing any dirt, grease, or debris that might hinder the bonding process. A simple solution of soap and water can effectively clean the area, followed by a thorough rinse to eliminate all residue. For more challenging surfaces, like those with paint overspray or rust, specialized cleaners designed for auto body work should be used. These products not only cleanse but also prime the metal, creating a clean slate for fastener installation.

After cleaning, treating the surface with an appropriate primer is crucial, especially in cases of damaged or corroded panels. This step fills in any imperfections and provides a smooth base for painting. In collision repair centers, where precision is key, this preparation phase is often enhanced with specialized tools and techniques, such as sandblasting or media blasting, to ensure the surface is ready for the next stage of auto body fasteners application, whether it’s for car dent removal or fleet repair services.

Installation Tips to Ensure Secured and Longevity Fasteners

When installing auto body fasteners, ensuring they’re securely fastened is paramount for both safety and aesthetics. Begin by preparing the surfaces thoroughly; clean them to remove any debris or contaminants that could compromise adhesion. Using the right tools, such as impact drivers or torque wrenches, is crucial. Tighten fasteners to the manufacturer’s recommended specifications, avoiding over-tightening which can lead to damage. For maximum longevity, consider using high-quality fasteners designed for automotive applications, which offer superior resistance to corrosion and strain.

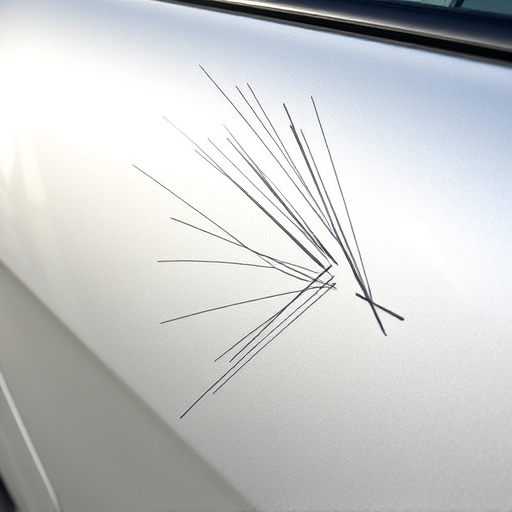

Additionally, proper alignment is key. Ensure the holes are perfectly aligned before inserting the fasteners; misalignment can result in poor fitment and eventual loosening. Regular maintenance includes periodic checks to ensure all fasteners remain tightly secured, addressing any that show signs of wear or loosening promptly. Remember, a solid fastener installation contributes significantly to your vehicle’s overall structural integrity, ensuring it withstands minor incidents like fender benders or tire services while preserving the car’s appearance and preventing unsightly car scratch repairs.

By understanding different auto body fastener types, properly preparing surfaces, and following installation best practices, you can significantly reduce common mistakes. These simple steps ensure secure, durable connections that contribute to a safer, more reliable vehicle. Remember, quality auto body fasteners are key to maintaining your car’s structural integrity.