Auto body fasteners are crucial for vehicle structural integrity and aesthetic appeal, ranging from standard nuts to specialized clips and rivets with unique functions. In collision repair, snap-in retainers facilitate panel replacement while rivets offer high resistance and alignment. Choosing and installing the right fastener prevents weak repairs and long-term damage; following meticulous preparation steps, using proper tools, and adhering to guidelines prevent common issues like misaligned panels, rust, and corrosion.

“Avoid common pitfalls with auto body fasteners and ensure your vehicle’s repair is done right. This guide delves into the intricacies of understanding different fastener types and their applications, providing critical insights for effective installation. By mastering these techniques, you can prevent damage and identify potential issues early on.

We’ll explore common mistakes, offering practical tips to ensure durability and long-lasting repairs. From proper tool selection to surface preparation, gain expert knowledge on auto body fasteners.”

- Understanding Auto Body Fastener Types and Their Uses

- Proper Installation Techniques to Avoid Damage

- Common Issues and How to Identify and Prevent Them

Understanding Auto Body Fastener Types and Their Uses

Auto body fasteners play a crucial role in ensuring the structural integrity and overall appearance of vehicles. Understanding the different types and their applications is key to effective collision repair. From nuts and bolts to specialized clips and rivets, each fastener serves a unique purpose. For instance, while regular nuts and bolts are versatile and commonly used for various components like panels and frames, they might not be suitable for areas requiring high resistance or specific alignment.

In the realm of collision repair, especially during bumper repair or auto glass replacement, specialized fasteners are often required. These may include snap-in retainers for easy panel removal and reinstallation, or rivets for securing parts in places that demand strength and stability. Knowing which fastener to use for what purpose ensures not just a sturdy fix but also prevents the need for frequent replacements, a common issue arising from using incompatible fasteners.

Proper Installation Techniques to Avoid Damage

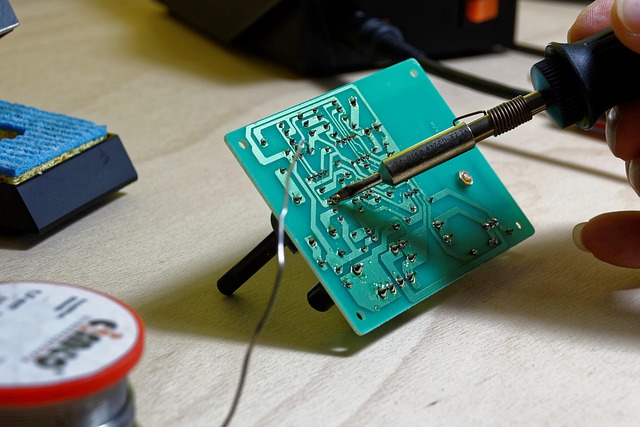

Proper installation techniques are paramount when working with auto body fasteners to prevent unnecessary damage. Every auto repair shop should emphasize the importance of using the correct tools and following manufacturer guidelines. This includes measuring twice before drilling or fastening, as incorrect spacing can compromise structural integrity. Professional technicians know that a little extra time spent on preparation pays off in long-term durability.

Additionally, understanding the type of fasteners suitable for specific automotive body work is crucial. Different materials and designs require distinct installation methods to avoid collision damage repair issues down the line. Proper training ensures that auto body fasteners are securely fastened without causing distress to the surrounding panels or components, enhancing the overall quality of the repair in an auto shop setting.

Common Issues and How to Identify and Prevent Them

Common issues with auto body fasteners include misaligned panels, loose or missing screws, and rust or corrosion that weakens fastener integrity. To identify these problems, inspect your vehicle for signs of misalignment, such as uneven gaps between panels or visible gaps along joints. Perform a thorough check for loose or absent fasteners using a torque wrench, especially in areas prone to damage during a fender bender or dent repair. Look out for rust or corrosion on metal surfaces and fastener heads, which can be indicative of moisture intrusion during vehicle restoration projects.

Preventing these issues involves implementing meticulous preparation and quality control measures. Use proper alignment tools when replacing panels to ensure precise fitting. Regularly inspect fasteners for signs of damage or wear and replace them as needed. Apply protective coatings like rust preventatives before exposing metal surfaces to the elements, especially during extensive dent repair or vehicle restoration projects.

By understanding the different types of auto body fasteners, their specific applications, and implementing precise installation methods, you can significantly reduce common issues like misalignment, damage to panels, and weak hold. Regularly inspecting your vehicle for signs of loose or corroded fasteners and addressing them promptly is equally crucial in maintaining a safe and reliable ride. Remember, proper care and knowledge of auto body fasteners go a long way in preserving the integrity of your vehicle’s structure.