Auto body fasteners are crucial for vehicle safety and structural integrity, with various types requiring precise understanding for effective installation. Correct torque settings prevent damage, warping, and ensure joint strength. Regular checks and replacements in routine maintenance are vital. Following a step-by-step guide ensures proper installation, mastery of which yields structurally sound auto body repair outcomes.

Auto body fasteners are crucial for maintaining vehicle integrity and safety. This guide delves into the essential practice of installing these components with precise torque settings. Understanding different fastener types and their functions is key, as proper tightening ensures structural stability and prevents costly repairs. Learn how to navigate this process step-by-step, ensuring every fastener is secured correctly for a safe, reliable ride.

- Understanding Auto Body Fastener Types and Their Functions

- The Importance of Correct Torque Settings for Safety

- Step-by-Step Guide to Installing Fasteners with Precision

Understanding Auto Body Fastener Types and Their Functions

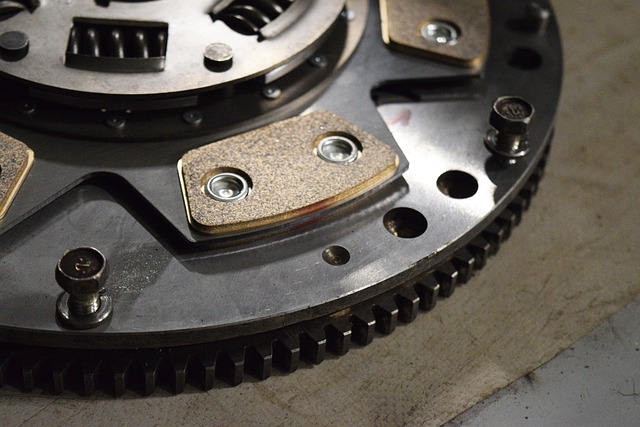

Auto body fasteners are essential components in ensuring the structural integrity and safety of vehicles. These fasteners come in various types, each designed for specific functions. For instance, bolt circles and studs secure panels to frames, while rivets provide permanent fastening solutions. Understanding these different auto body fasteners is crucial for effective installation and maintenance, especially during scratch repair or fleet repair services.

Different materials and construction methods determine the appropriate torque settings for each type of auto body fastener. Proper torque ensures that components are securely fastened without being overly tightened, which could lead to damage or warping. Regular checks and replacements of these fasteners as part of routine auto maintenance are vital to prevent accidents and keep vehicles in top condition.

The Importance of Correct Torque Settings for Safety

Correct torque settings for auto body fasteners are paramount for both performance and safety during vehicle repair services or collision repair processes. Improperly torqued fasteners can lead to weak joints, reduced structural integrity, and even catastrophic failure during driving, putting at risk the safety of drivers and passengers.

Proper torque ensures that auto body fasteners, like bolts and screws, hold firmly in place, maintaining the precision alignment crucial for frame straightening. This is especially critical in areas like the chassis, suspension, and body panels where even slight misalignments can compromise handling, stability, and overall vehicle safety. By adhering to recommended torque specifications, technicians ensure the longevity and structural soundness of vehicles, preventing future issues that could impact both performance and safety during operation.

Step-by-Step Guide to Installing Fasteners with Precision

Installing auto body fasteners with precision is a critical step in ensuring the structural integrity and longevity of any vehicle body shop or car body repair project. Here’s a step-by-step guide to help you achieve this:

1. Preparation: Gather the necessary tools, including torque wrenches calibrated for your specific fastener types. Inspect the surfaces where the fasteners will be applied to ensure they are clean and free from debris. This is crucial for a secure bond.

2. Alignment: Align the fasteners correctly before tightening. Use templates or reference points provided by the manufacturer to ensure proper placement. In car collision repair, precise alignment minimizes visible imperfections after the fastener installation.

3. Initial Torquing: Apply the first layer of torque as per the manufacturer’s specifications. This initial step sets the base for subsequent torques, ensuring that fasteners are seated correctly without overtightening. Remember, too much force can damage threads or even crack panels in a delicate car body repair scenario.

4. Sequential Torquing: Follow the progressive torque sequence recommended for each fastener type. This involves tightening in stages, increasing torque at each step as specified by the vehicle body shop’s guidelines or the fastener manufacturer’s recommendations.

5. Final Check: Once all fasteners are secured, perform a thorough visual inspection. Ensure that every bolt is firmly in place and there are no signs of over-tightening. In a well-executed car collision repair, the final result should be a seamless, structurally sound vehicle body.

Properly installing auto body fasteners with the right torque settings is paramount for both structural integrity and passenger safety. By understanding different fastener types and adhering to recommended torque specifications, automotive technicians can ensure vehicles meet rigorous safety standards. This meticulous process, detailed in our guide, underscores the importance of precision in vehicle repair and maintenance. Armed with this knowledge, folks can rest assured that their vehicles are not only running smoothly but also securely.