Auto body fasteners play a crucial role in preserving structural integrity and aesthetic appeal for vehicles with aluminum or steel bodies. Selection requires understanding metal properties: aluminum needs lightweight, strong fasteners, while steel demands corrosion-resistant solutions. Installation methods vary from threaded fasteners for security to clip-on/snap fasteners for quick assembly. Best practices for installation include using impact drivers for aluminum and thread locker for prevention of loosening. For steel, traditional methods like drilling and tapping are employed with high-quality fasteners like bolt kits or rivets, ensuring precise alignment during dent repair.

In today’s automotive industry, using aluminum and steel bodywork has become increasingly common due to their lightweight yet durable properties. However, joining these materials requires specific auto body fasteners to ensure structural integrity and longevity. This article explores the critical aspects of selecting the right fasteners for both aluminum and steel bodies, delving into different types, key considerations, and installation techniques to help professionals achieve optimal performance in vehicle repairs and renovations.

- Understanding Auto Body Fastener Types for Aluminum and Steel

- Key Considerations When Choosing Fasteners for Different Metal Bodies

- Installation Techniques and Best Practices for Optimal Performance

Understanding Auto Body Fastener Types for Aluminum and Steel

Auto body fasteners play a crucial role in ensuring the structural integrity and overall aesthetics of vehicles with aluminum or steel bodywork. Understanding the types designed specifically for these materials is essential when undertaking either car dent removal or extensive car body restoration projects. These fasteners are formulated to withstand the unique properties of each material, offering both strength and corrosion resistance.

For aluminum bodywork, auto body fasteners should be able to handle the lightweight yet delicate nature of this metal. This often involves using materials that can resist galvanic corrosion when in contact with steel components. In contrast, steel fasteners need to be robust enough to penetrate and hold firmly onto the harder surface, while also being compatible with various painting and coating techniques employed in modern automobiles. Properly selecting auto body fasteners is vital for seamless bodywork repairs, ensuring a sturdy finish that complements the vehicle’s overall appearance, whether it’s undergoing routine maintenance or major autobody repairs.

Key Considerations When Choosing Fasteners for Different Metal Bodies

When selecting auto body fasteners for aluminum or steel bodywork, several key considerations come into play. The primary factor is understanding the specific metal type, as each material has unique properties that require tailored fastening solutions. Aluminum, known for its lightweight nature and corrosion resistance, often necessitates fasteners with superior strength to match its strength-to-weight ratio. On the other hand, steel, with its higher weight and potential for rust, demands fasteners designed to withstand corrosion and provide lasting hold.

Additionally, the method of fastener installation and removal plays a crucial role in car collision repair or car restoration projects. For example, in high-pressure applications or when dealing with intricate body panels, threaded fasteners might be preferred due to their ability to create secure, reusable bonds. Conversely, clip-on or snap fasteners could be more suitable for quick assembly and disassembly, which is often required during car body restoration processes. Choosing the right fastener type ensures structural integrity, facilitates efficient repair or restoration work, and ultimately contributes to a vehicle’s overall performance and longevity.

Installation Techniques and Best Practices for Optimal Performance

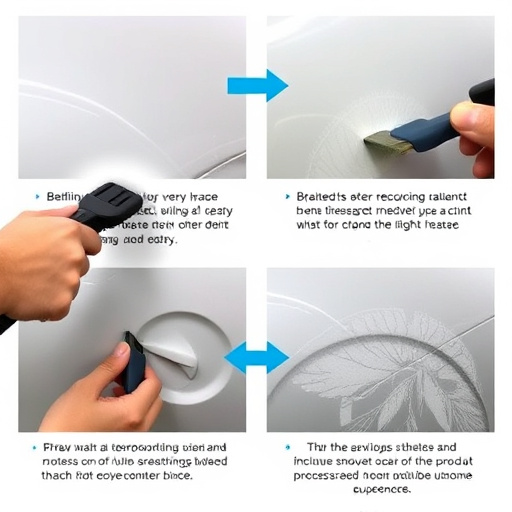

When it comes to installing auto body fasteners for aluminum or steel bodywork, understanding the techniques and best practices is key to achieving optimal performance. For aluminum panels, which are lightweight yet prone to deformation, a precise approach is essential. This involves using specialized tools like impact drivers or air guns to ensure fast and accurate fastening without damaging the delicate metal. Additionally, applying a thin layer of thread locker can prevent fasteners from loosening over time, a crucial step in vehicle restoration projects where precision matters.

For steel bodywork, which offers more structural integrity, a slightly different strategy applies. Here, traditional methods such as drilling and tapping holes can be employed, followed by the use of high-quality auto body fasteners like bolt kits or rivets. Proper alignment is critical to avoid misalignment during vehicle dent repair, ensuring that panels fit seamlessly together. In cases like Mercedes Benz collision repair, where precision and quality are paramount, following these best practices guarantees a sturdy and durable repair, restoring the vehicle’s structural integrity without compromising its original aesthetic appeal.

Auto body fasteners play a crucial role in ensuring structural integrity and the overall quality of vehicle repairs. When working with aluminum or steel bodywork, understanding the specific fastener types and making informed choices are essential. By considering factors like material compatibility, thread design, and installation methods, you can achieve superior results. With the right auto body fasteners, professionals can navigate the intricate process of repair, ensuring a durable and reliable finish that meets modern automotive standards.